The laboratory was organized in 1989 to promote development of methods of assessment of structural reliability, mostly in ship and marine applications. In mid-nineties the two groups were formed: one, engaged in development of analytical methods and numerical simulation of soil and media with inhomogeneities, cavities and another, work of which is focused on problems on mechanics of fatigue damage and failure of materials and structures.

Initially, the group worked in cooperation with SPb Marine Technical University, Central Marine Research Institute, Russian Register of Shipping. On the partnership terms research was carried out with Politechnika Gdanska (Poland), Rostock University, Technische Universitat Hamburg-Harburg (Germany) focused on studies of deformation and failure of steels and alloys, welded structures. Consultative works were carried out for a ship design bureau in St.Petersburg addressed to problem of reliability of bulge keel structures, of ship superstructures at expansion joints.

In 2003–2009 the lab cooperated with the Lloyd's Register of Shipping (UK) which allowed further development of the insight into the problems of in-service reliability of structures. Respectively, were designed study courses for SPb Polytechnic University, in particular, for international master programs. Lab keeps cooperation with Research department of Russian Register of Shipping. In 2014–2016 we carried out cooperative work with colleagues from Dortmund University (Germany), participated in teaching within Weeks of Science program at the Tampere University of Applied Sciences (Finland).

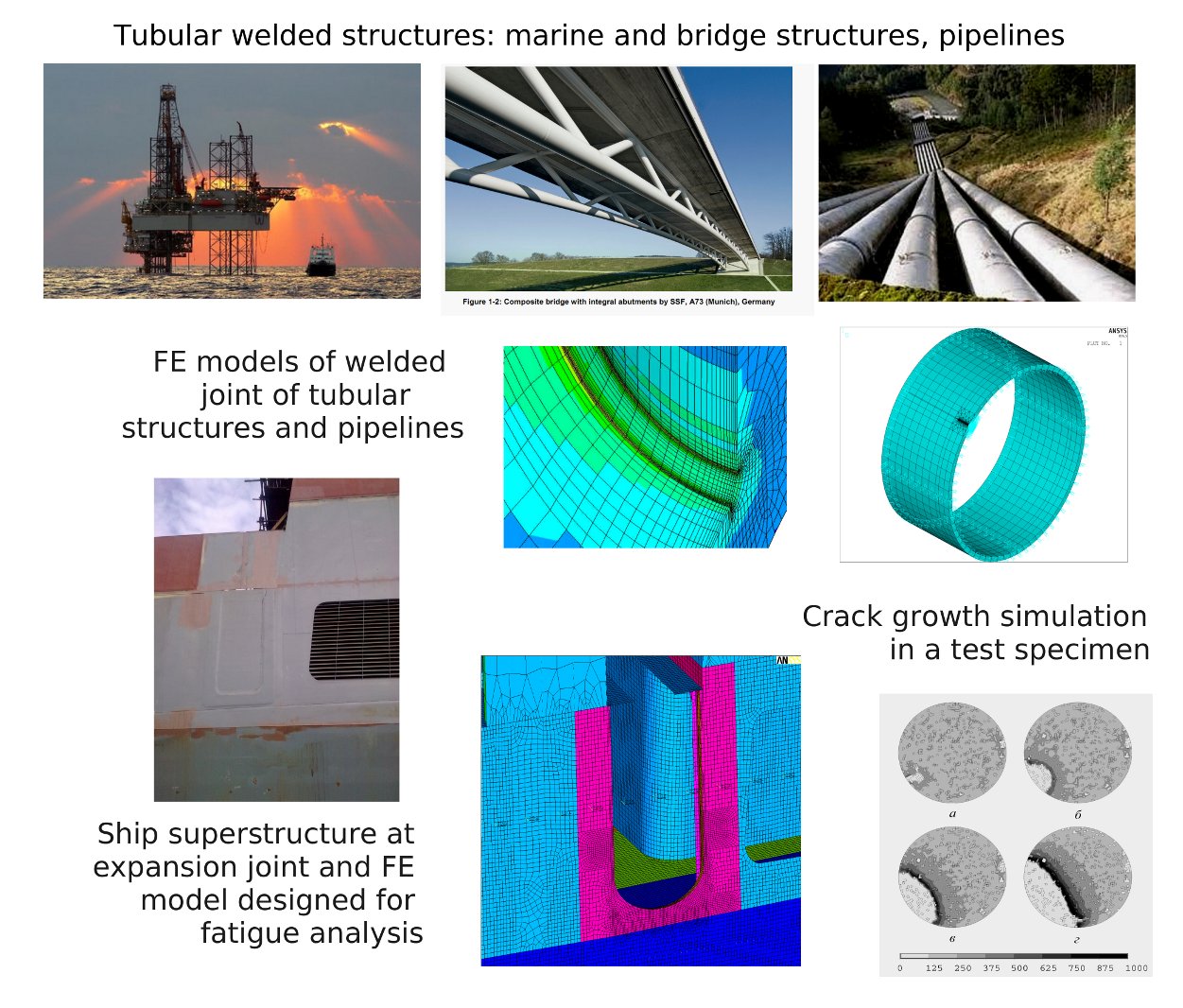

The research works of the group are focused on development of approaches and modeling of fatigue damage and failure of structures through service life prior to onset of a critical condition. The approaches are based on numerical modeling of deformation and damage accumulation processes in polycrystalline structure of materials with account for stochastic properties of the micro- and macroplastic straining of material elements under variable loading. Characterization of structural elements is based on results of systematic experimental studies of deformation and fatigue of steels and aluminium alloys carried in Marine Technical University and by colleagues in foreign universities. Criteria of failure are defined in dependence of the selected approach: Strain-life, Inelastic strain energy, in combination with the criteria of Linear Elastic Fracture Mechanics. Efficiency of approaches was demonstrated in examples of analyses of reliability of pipelines subjected to intensive pulsations of pressure, tubular bridge and marine structures, ship hull structures.

Results of the group works are being presented at international and national conferences: International Summer Schools APM, National conference “Current problems of development of Shipbuilding and Shipping 2015” (Russian Register of Shipping), National conference “Applied topics of mechanics of solids in shipbuilding”, dedicated to V.V.Novozhilov's anniversary (2010, Krylov Research Center), International conference “Innovative Materials, Structures and Technologies-2013” (Riga, Latvia), TAMK International Week for Engineering (2013–2014, Tampere, Finland), “DYN-WIND-2014” (Slovakia), 2014 International Conference on Manufacturing Science and Engineering (Shanghai, CPR), METNET-2014 (St.Petersburg), SPbUCEFM-2015 (St.Petersburg).